Are you tired of dealing with water that just doesn’t feel clean or tastes off? Your ion exchange resin might be the key to solving that problem, but only if it’s working at its best.

Over time, resin gets used up and loses its ability to purify water effectively. The good news? You can bring it back to life with a simple process called regeneration. You’ll discover exactly how to regenerate your ion exchange resin, saving money and improving your water quality.

Keep reading to learn the easy steps that will make your resin work like new again!

Basics Of Ion Exchange Resin

Understanding the basics of ion exchange resin is important before learning how to regenerate it. This resin is a special material that helps clean water and remove unwanted ions. It works by swapping harmful ions with safer ones.

Knowing what ion exchange resin is, its types, and common uses helps in proper handling. This knowledge makes resin regeneration easier and more effective.

What Is Ion Exchange Resin

Ion exchange resin is a small, solid bead made from organic material. These beads carry charged particles called ions. The resin swaps harmful ions in water with harmless ones. This process purifies water and removes minerals or pollutants.

Types Of Ion Exchange Resins

There are two main types of ion exchange resins: cation and anion resins. Cation resin removes positive ions like calcium and magnesium. Anion resin removes negative ions like chloride and sulfate. Some resins combine both types for better cleaning.

Common Uses Of Ion Exchange Resin

Ion exchange resins are used in many areas. They clean drinking water by removing hardness and salts. Industries use them to purify chemicals and treat wastewater. They also help in food processing and pharmaceutical production.

Credit: dardel.info

When To Regenerate Resin

Knowing when to regenerate ion exchange resin is key to keeping water clean and safe. Resin loses its ability to remove impurities over time. Regular checks help avoid poor water quality and damage to your system.

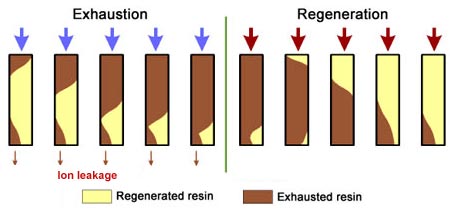

Signs Of Resin Exhaustion

Water tastes salty or strange. Hard water spots appear on dishes or fixtures. Water flow slows down. These signs show resin needs regeneration. Testing water hardness also reveals resin condition.

Factors Affecting Resin Lifespan

Water quality impacts resin life. High iron or chlorine levels cause faster wear. Frequent use shortens resin lifespan. Proper maintenance and correct regeneration extend resin use.

Preparation For Regeneration

Preparation is the first step in regenerating ion exchange resin. It sets the stage for a smooth, safe process. Proper preparation prevents damage and ensures effective resin regeneration.

This section covers safety, materials, and system shutdown before starting regeneration. Understanding these basics helps you avoid common mistakes.

Safety Precautions

Wear protective gloves and safety glasses at all times. Chemicals used in regeneration can harm skin and eyes. Work in a well-ventilated area to avoid inhaling fumes. Keep a first aid kit nearby. Read all safety instructions on chemical labels carefully. Never mix chemicals without guidance. Follow all local safety regulations strictly.

Required Materials And Equipment

Gather all necessary materials before starting. You will need regeneration chemicals like salt or acid. Prepare clean water for rinsing the resin. Have measuring tools ready to ensure correct chemical doses. Use containers resistant to chemicals for mixing. Ensure you have a proper disposal method for waste. Keep tools like brushes and funnels handy for cleaning and handling resin.

Shutting Down The System

Turn off the water supply to the ion exchange system. Release any pressure inside the system slowly. Close all valves connected to the resin tank. Drain the resin tank completely to remove old water. Disconnect the system from power if it has electrical parts. Check that no water or power remains active before starting regeneration. This step protects both you and the equipment.

Step-by-step Regeneration Process

Regenerating ion exchange resin is essential to keep water treatment systems working well. This process restores the resin’s ability to remove unwanted ions. Follow these clear steps to regenerate the resin safely and effectively.

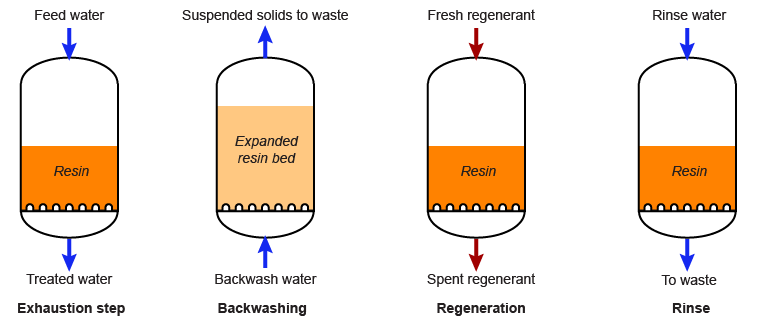

Backwashing The Resin Bed

Start by backwashing the resin bed. This step removes dirt and debris from the resin. Run water upward through the resin to loosen trapped particles. Continue until the water runs clear. Backwashing also helps to fluff the resin beads. This improves their contact with the regenerant.

Applying Regenerant Solution

Next, apply the regenerant solution. Use the right chemical for your resin type. Slowly pass the solution through the resin bed. The regenerant replaces the ions the resin captured. Let it soak for the recommended time. This step restores the resin’s ion exchange capacity.

Rinsing And Flushing The Resin

After regeneration, rinse the resin bed thoroughly. Flush it with clean water to remove excess regenerant. Continue rinsing until no chemical taste or smell remains. Proper rinsing prevents contamination of your treated water.

Restoring Normal Operation

Finally, return the system to normal operation. Adjust the flow rate to the usual level. Monitor water quality to ensure the resin works well. Regular checks help maintain the resin’s performance over time.

Tips For Effective Regeneration

Effective regeneration of ion exchange resin ensures the resin works well for a longer time. Follow these tips to get the best results. Proper care keeps the resin clean and ready to remove unwanted ions.

Choosing The Right Regenerant

Select a regenerant that matches your resin type. For cation resins, use salt (NaCl). For anion resins, use caustic soda (NaOH). Use fresh chemicals to avoid poor regeneration. Avoid mixing regenerants as it can damage the resin.

Optimal Contact Time

Allow enough time for the regenerant to react with the resin. Usually, 30 to 60 minutes works well. Too short contact time leaves the resin dirty. Too long contact time wastes chemicals and can harm the resin.

Avoiding Common Mistakes

Do not use dirty water for regeneration. Clean water helps the resin stay effective. Avoid overusing regenerant; it can cause resin swelling. Never rush the process. Follow the recommended steps carefully for best results.

Credit: dardel.info

Maintaining Ion Exchange Resin

Maintaining ion exchange resin is key to its performance and durability. Proper care helps the resin work efficiently for a longer time. This reduces costs and avoids frequent replacements. Understanding how to maintain the resin ensures clean water and smooth operation.

Regular Monitoring

Check the resin condition often. Look for changes in color or texture. Test water quality regularly to spot issues early. Monitor flow rates to detect blockages or resin exhaustion. Keep a log of these checks for future reference.

Preventative Measures

Use pre-filters to remove large particles before the resin. Avoid exposing resin to harsh chemicals that can damage it. Control water temperature and pH to stay within safe limits. Rinse resin beds after each regeneration to remove debris.

Extending Resin Life

Follow the recommended regeneration schedule closely. Use the right type and amount of regenerant chemical. Avoid overloading the system with hard water. Store resin properly if not in use for a long time. Clean resin tanks periodically to prevent contamination.

Credit: www.sciencedirect.com

Frequently Asked Questions

What Is Ion Exchange Resin Regeneration?

Ion exchange resin regeneration restores the resin’s ability to remove unwanted ions. It involves flushing with a regenerant solution, like salt or acid. This process removes trapped ions and renews the resin’s effectiveness for water treatment.

How Often Should You Regenerate Ion Exchange Resin?

Regeneration frequency depends on resin use and water quality. Typically, resin needs regeneration every few weeks to months. Regular monitoring ensures optimal performance and prevents resin exhaustion, maintaining efficient ion exchange.

What Chemicals Are Used To Regenerate Ion Exchange Resin?

Common regenerants include sodium chloride (salt) for cation resins and sodium hydroxide or hydrochloric acid for anion resins. These chemicals displace contaminants, restoring the resin’s ion exchange capacity effectively.

Can Ion Exchange Resin Be Regenerated Multiple Times?

Yes, ion exchange resin can be regenerated multiple times. Proper regeneration extends resin life and maintains performance. However, resin eventually degrades and requires replacement after many cycles.

Conclusion

Regenerating ion exchange resin keeps your water clean and safe. Follow the steps carefully for best results. Regular care helps the resin last longer. Avoid common mistakes to save time and money. Proper regeneration restores resin’s ability to remove impurities.

Simple actions make a big difference in water quality. Keep your system working well with routine maintenance. Clean resin means better water for your home or business. Stay consistent for reliable and fresh water every day.

Hasan Al Sarker is a Reverse Osmosis Specialist. He has worked for many years to ensure safe drinking water for all. His research paper has been published in several journals, including Issue, Medium, and Slideshare. He is recognized as a water doctor among specialists though he did not attend medical college.

Besides working as a researcher of reverse osmosis technology, he is also very fancy with the kitchen and cooking. His guides are reading thousands of people every day. As a head of content, he is responsible for all the published articles at RO System Reviews.