Are you curious about how to get the most out of ion exchange resin? Whether you’re dealing with hard water, purifying chemicals, or improving water quality, understanding how to use ion exchange resin can make a huge difference.

In this guide, you’ll discover simple steps to use this powerful material effectively. By the end, you’ll feel confident handling ion exchange resin and unlocking its full potential for your needs. Keep reading to learn exactly what you need to do!

Credit: en.wikipedia.org

Basics Of Ion Exchange Resin

Ion exchange resin is a special material used to remove unwanted ions from liquids. It works like a filter but swaps ions instead of trapping particles. This process helps clean water, treat chemicals, and even improve food quality.

Understanding the basics of ion exchange resin makes it easier to use in many ways. Here are the main points to know about these resins.

Types Of Ion Exchange Resins

There are two main types of ion exchange resins: cation and anion resins. Cation resins swap positive ions like calcium and magnesium. Anion resins swap negative ions like chloride and sulfate. Some resins can do both, called mixed bed resins. Each type works best for certain tasks.

How Ion Exchange Works

The resin contains charged sites that attract opposite ions. When water passes through, ions in the water swap places with ions on the resin. For example, calcium ions in water swap with sodium ions on the resin. This exchange cleans the water by removing unwanted ions.

Common Applications

Ion exchange resins are widely used in water softening to reduce hardness. They also help in water purification for drinking and industrial use. In food production, resins remove acids and impurities. Chemical industries use resins to separate and purify different substances. These resins play a key role in many everyday processes.

Choosing The Right Resin

Choosing the right ion exchange resin is key for effective water treatment. Different resins serve different purposes. Picking the wrong one can reduce efficiency and increase costs. Understanding your needs helps make the best choice.

Factors To Consider

Water quality affects resin choice. Test your water for hardness, pH, and contaminants. Resin type depends on the ions you want to remove or exchange. Consider resin capacity and flow rate. Space and budget also matter in your decision.

Matching Resin To Application

Cation resins remove positive ions like calcium and magnesium. Anion resins target negative ions such as nitrate or sulfate. Mixed-bed resins handle both types for high purity. Choose based on whether you treat drinking water, industrial water, or wastewater.

Quality Indicators

Check resin bead size and uniformity. Good resin has consistent beads for better flow. Purity levels show how clean the resin is. Look for certifications or test reports from suppliers. High-quality resin lasts longer and performs better.

Preparing Resin For Use

Preparing ion exchange resin correctly ensures it works well and lasts longer. This step improves the resin’s ability to clean water or other fluids efficiently. Proper preparation avoids problems like clogging or poor performance.

Cleaning And Conditioning

Start by rinsing the resin with clean water to remove dust and debris. Use a gentle flow to avoid breaking the resin beads. After rinsing, soak the resin in a conditioning solution. This helps the resin gain its full ion exchange capacity. Follow the manufacturer’s instructions for the right type of solution and soaking time. Conditioning restores the resin’s active sites for better ion exchange.

Proper Storage Practices

Store the resin in a cool, dry place when not in use. Keep it away from direct sunlight and extreme temperatures. Always keep the resin moist by storing it in water or a preservative solution. Dry resin can lose its effectiveness quickly. Use sealed containers to prevent contamination. Proper storage maintains the resin’s quality and readiness for future use.

Installation Tips

Installing ion exchange resin correctly ensures the system works well and lasts long. Proper setup avoids problems and saves time. Follow these simple tips for a smooth installation process.

Setting Up Equipment

Begin by checking all equipment parts for damage or dirt. Clean tanks and pipes before adding resin. Use the right size resin for your system. Place the resin carefully to avoid gaps or air pockets. Connect pipes tightly to stop leaks. Test water flow to confirm proper setup.

Avoiding Common Mistakes

Do not mix different resin types in one tank. Avoid overfilling the resin bed; it can cause poor water flow. Keep resin away from direct sunlight and extreme heat. Do not skip rinsing the resin before use. Make sure valves are open or closed as needed. Regularly inspect the system after installation for any issues.

Optimizing Resin Performance

Optimizing ion exchange resin performance is key for efficient water treatment. Proper care extends resin life and improves results. Small adjustments can make a big difference in resin effectiveness.

Flow Rate Management

Control the flow rate through the resin bed carefully. Too fast flow reduces contact time and lowers ion exchange. Too slow flow can cause channeling and uneven resin use. Keep flow within the recommended range for best results.

Temperature And Ph Control

Maintain temperature within the resin’s operating range. High temperatures can damage the resin beads. pH levels affect resin capacity and selectivity. Avoid extreme pH values to protect resin structure and function.

Regular Monitoring Techniques

Check resin condition often to catch issues early. Monitor water quality before and after treatment. Use pressure gauges to detect clogging or fouling. Regular tests help decide when to regenerate or replace resin.

Maintenance And Regeneration

Proper maintenance and timely regeneration keep ion exchange resin working well. Resin cleans water by trapping unwanted ions. Over time, it loses its ability to do this effectively. Regular care restores resin’s strength and ensures it lasts longer.

When To Regenerate

Resin needs regeneration when water flow slows or quality drops. Test water hardness or salt levels often. A change means resin is full of trapped ions. Regenerate before performance gets poor. This avoids damage to the resin and system.

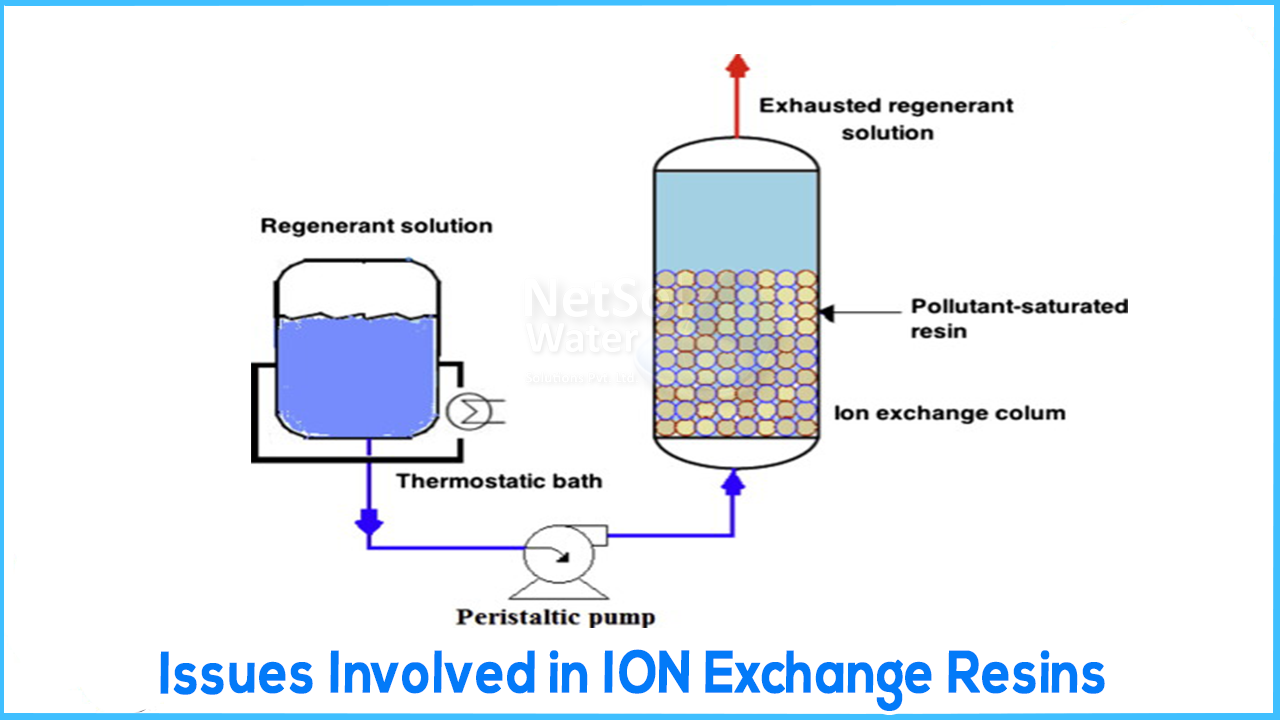

Regeneration Procedures

Start by flushing the resin with a salt solution or chemical. This removes trapped ions and recharges the resin. Follow the manufacturer’s instructions carefully. Use the right amount of regenerant for best results. After soaking, rinse the resin to clear out leftovers. Avoid rushing this step to prevent damage.

Extending Resin Lifespan

Keep resin clean by regular backwashing to remove debris. Use soft water for rinsing to reduce mineral buildup. Avoid harsh chemicals that can harm the resin. Monitor system pressure and flow rates often. Proper storage during long breaks protects resin from drying out. Regular checks and care help the resin last years.

Troubleshooting Problems

Troubleshooting problems with ion exchange resin helps keep your system working well. Regular checks can find issues early. Fixing problems fast saves time and money.

Identifying Resin Fouling

Resin fouling happens when dirt or minerals cover the resin beads. This blocks the resin from working right. Signs include low flow rate and poor water quality. Check for color change or slimy texture on the resin. Test the water before and after the resin to see if fouling is the cause.

Addressing Reduced Efficiency

Reduced efficiency means the resin does not clean water well. This can happen from fouling or wrong regeneration. Make sure you use the correct amount of regenerant. Clean the resin by backwashing or chemical cleaning. Replace the resin if it still works poorly after cleaning.

Handling Resin Breakdown

Resin breakdown happens over time from harsh chemicals or heat. Broken resin beads cause poor water treatment. Look for resin dust or soft, sticky beads. Replace the resin immediately if breakdown occurs. Avoid strong chemicals and high temperatures to protect the resin.

Credit: www.netsolwater.com

Safety Precautions

Using ion exchange resin requires careful attention to safety. These resins can contain chemicals that may be harmful if handled incorrectly. Following safety rules protects your health and the environment. Always prepare before working with ion exchange resins.

Handling Chemicals Safely

Wear protective gloves and safety goggles at all times. Avoid direct contact with the resin and its liquids. Work in a well-ventilated area to reduce inhaling fumes. Do not eat or drink near the resin. Wash your hands thoroughly after handling.

Disposal Guidelines

Dispose of used resin according to local regulations. Do not pour resin or its waste into drains or water sources. Place waste in sealed containers before disposal. Contact your local waste management for proper disposal methods. Proper disposal prevents environmental pollution and health risks.

Credit: www.ionicsystems.com

Frequently Asked Questions

What Is Ion Exchange Resin Used For?

Ion exchange resin removes unwanted ions from liquids. It purifies water, softens hard water, and recovers valuable metals. It is widely used in water treatment, chemical processing, and pharmaceuticals.

How Does Ion Exchange Resin Work?

The resin exchanges ions between its surface and the liquid. It traps unwanted ions and releases beneficial ions. This process effectively cleans or softens the liquid.

Can Ion Exchange Resin Be Regenerated?

Yes, ion exchange resin can be regenerated. Using salt or acid solutions restores its ion exchange capacity. This extends the resin’s lifespan and maintains its efficiency.

What Types Of Ion Exchange Resins Exist?

There are cation and anion exchange resins. Cation resins remove positive ions, while anion resins remove negative ions. Each type suits specific purification needs.

Conclusion

Using ion exchange resin helps clean and soften water effectively. It removes unwanted minerals and improves water quality. Regular care keeps the resin working well over time. This process is simple and saves money on bottled water. Understanding how to use it ensures better results at home or work.

Try it today to enjoy cleaner, softer water every day.

Hasan Al Sarker is a Reverse Osmosis Specialist. He has worked for many years to ensure safe drinking water for all. His research paper has been published in several journals, including Issue, Medium, and Slideshare. He is recognized as a water doctor among specialists though he did not attend medical college.

Besides working as a researcher of reverse osmosis technology, he is also very fancy with the kitchen and cooking. His guides are reading thousands of people every day. As a head of content, he is responsible for all the published articles at RO System Reviews.